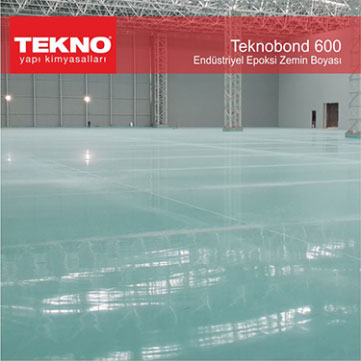

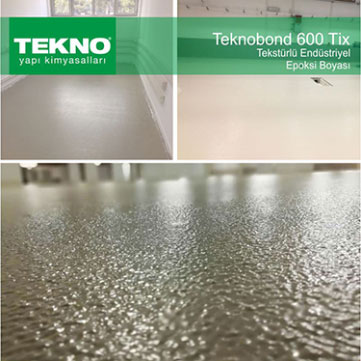

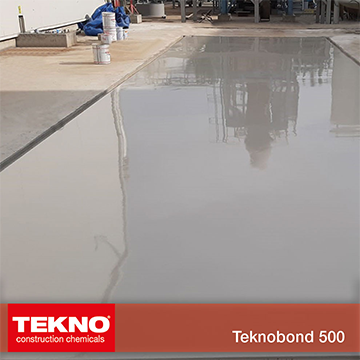

TEKNOBOND 500, two component, epoxy resin-based, self levelling coating.

TEKNOBOND 500, two component, epoxy resin-based, self levelling coating.Areas of Usage

• Self levelling systems for the concrete and cement mortar edsurfaces exposed to normal medium heavy load such as maintenance workshops, garages and loading ramps ete.

• Multi-storey and underground parking garage

• Sand blasting systems are recommended for wet operation field in food and beverages industries and maintenance shelters.

Features and Benefits

• Can befilled with high level offilling.

• Good chemical and mechanical strength.

• Easy applicable. No solvent required.

• Economic

• Liquid impermeable

• Glossyfinish.

• Nonskid surface can be obtained

Application lnstructions

Surface Ouality:The surface should be dry and free from all kinds of dust, dirt, weak and loose tools, cement slurry residue and grease oil. The lower surface of concrete should be clean, strong and with sufficient compression resistance (minimum 25N/mm 2) and pull-off strength at least1.5 N/mm2.

Surface Preparation: The surface should be cleaned by using appropriate methods in order to provide maximum adhesion strength.

Compound: After the component B is added to the component A, mix for 2-3 minutes with a low speed, electrical mixer (maximum 400 revolution per minute) until a homogenous color is obtained.

Application Notes / Restrictions

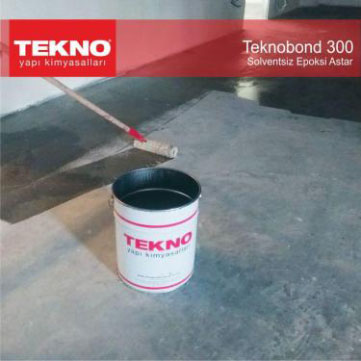

• Make sure that TEKNOBOND 500 covers a continuous, non-porous surface. lf necessary, apply TEKNOBOND 300 priming coat application twice. TEKNOBOND 500 is applied with notched rowel.

• in order to complete the hardening of the material, do not use it allowed minimum temperature. Low temperatures will slow down the hardening, while high temperatures will accelerate the hardening. The pot life will also vary depending on the temperature.

• The product may irritate the skin. Protective glasses or gloves should be used. Protective hand cream should be used before starting work . lf the soil mixture contacts with eyes, eyes should be washed immediately with warm water, and consult doctor.

• Crystallization can be shown in the product if it is kept below 0°C fora long time. lf the crystals are broken by bringing the product back to room temperature, the product can be used without any problem.

• Discoloration and yellowing can be happened in the product which hardened depending on direct sunlight. After application, the product should be protected against direct sunlight, strong wind, high air temperature (above +35 °C), bad weather conditions such as rain and freeze. in order to complete the hardening and reaction shortly after the application, the areas that contacts with skin should be cleaned with water and detergent.

• lmmediately afterthe application, equipment should be cleaned with Tekno Thinner.